Wilfley Concentrating Table

DENVER-WILFLEY, Model 13-A

The concentrating table is a mechanical means of separating granular materials. The separation is influenced by the difference in specific gravity, shape and size of particles. The feed to the table has a solid/water ratio of 25%-75%. The speed of the table, length of the stroke, inclination of the deck, height of riffles and volume of water influence concentration of product.

Mozley Concentrating Table

MOZLEY

The Mozley Laboratory Separator quickly and efficiently separates mineral grains of a certain size class. The batch process uses 50-100 g sample. The ‘V’ profile tray is for the separation of 2 mm 50 100 µm size range. The flat tray is for the separation of 100 –10 µm size range. The four adjustments that affect separation are slope, speed, amplitude and wash water.

Centrifugal Gravity Separators

Falcon Concentrator

FALCON, Model Super Bowl 4

The Super Bowl takes advantage of the difference in specific gravity between gold and gangue minerals to realize a separation. The centrifugal force magnifies the difference in specific gravity and the rotor geometry facilitates retention of gold particles in preference to low SG particles that are rejected with the process rotor.

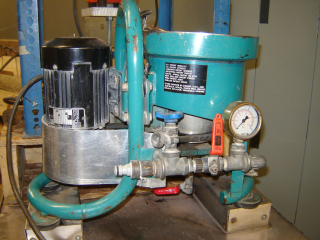

Knelson Concentrator

KNELSON, 3” Lab Model

The Knelson Concentrator takes advantage of the difference in specific gravity between gold and gangue minerals to realize a separation. The centrifugal force magnifies the difference in specific gravity and the rotor geometry facilitates retention of gold particles in preference to low SG particles that are rejected with the process rotor.

Modified Dry Knelson Concentrator

MODIFIED DRY KNELSON, 3” Lab Model

Working principles are the same with the KNELSON, 3” Lab Model. The only difference is instead of water, the Modified Dry Knelson uses air for fluidization.

Spiral Separator

Spiral separators are devices to separate solid components in a slurry, based upon a combination of the solid particle density as well as the particle's hydrodynamic properties (e.g. drag). The device consists of a tower, around which is wound a sluice, from which slots or channels are placed in the base of the sluice to extract solid particles that have come out of suspension.